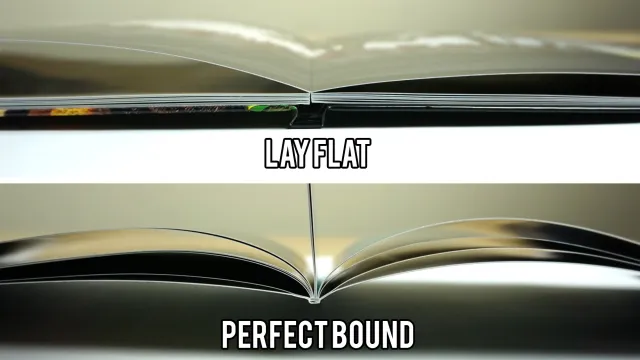

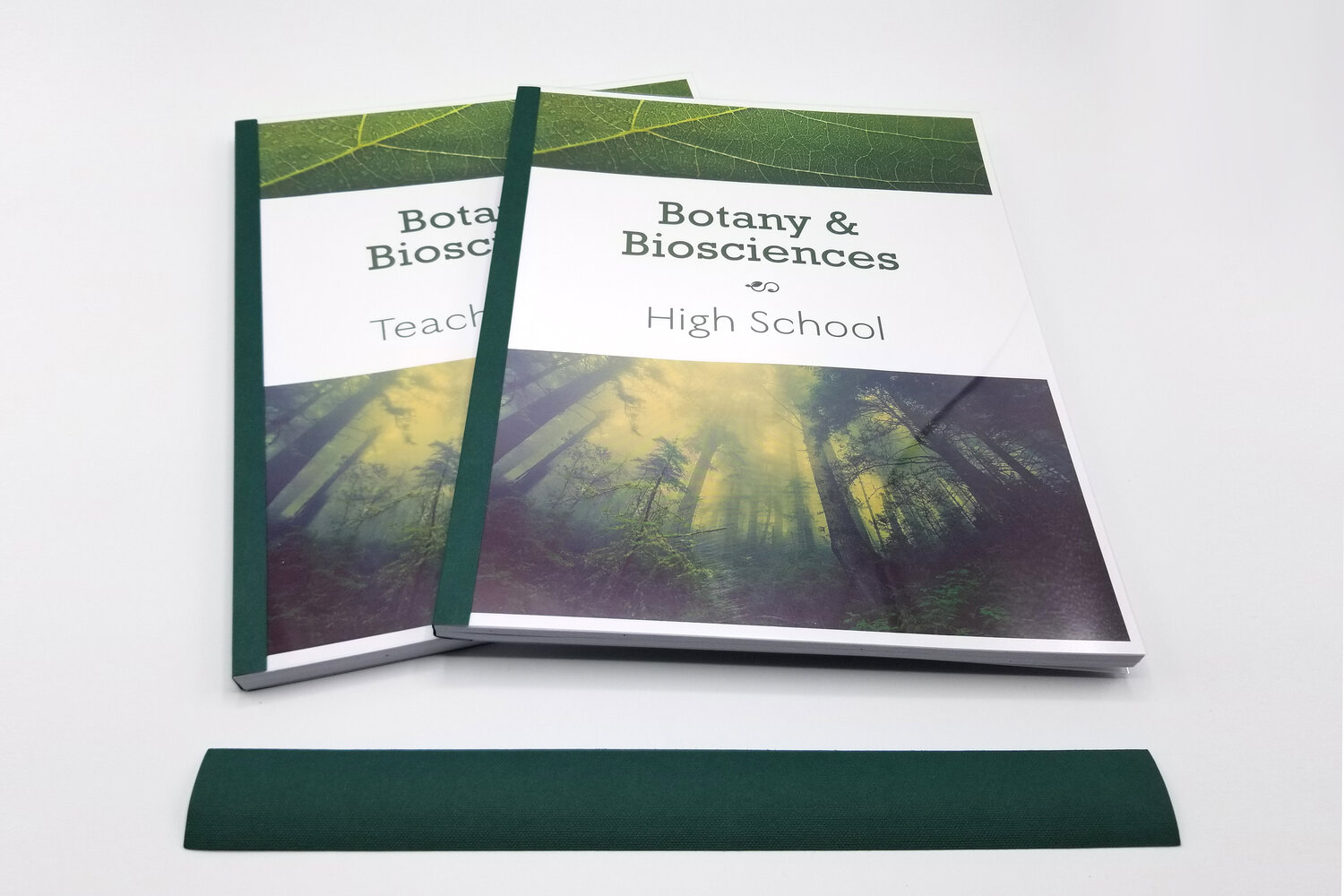

When creating a book, choosing the right binding style is important to ensure your photos and pages are displayed in the best way possible. Lay-flat and Perfect binding are two of the most popular options when making books. Both offer advantages and disadvantages that should be considered before making a decision. Here are five things to consider when deciding between lay-flat vs perfect binding for your book.

Durability

When it comes to durability, lay-flat binding is the clear winner. Lay-flat binding allows pages to lay completely flat when opened and prevents them from warping due to wear and tear over time. Both lay-flat binding and perfect binding at Graphic Finishing Services uses PUR adhesive glue, which allows for superior strength cause pages to stay together over time and use.

Cost

Cost is important when selecting the right binding type for a book. Lay-flat binding provides superior quality by allowing pages to lay flat without breaking or warping, but this comes at a higher cost, due to the extra work involved in preparing each page.

On the other hand, perfect binding is more affordable because of its simple construction process.

Design Flexibility

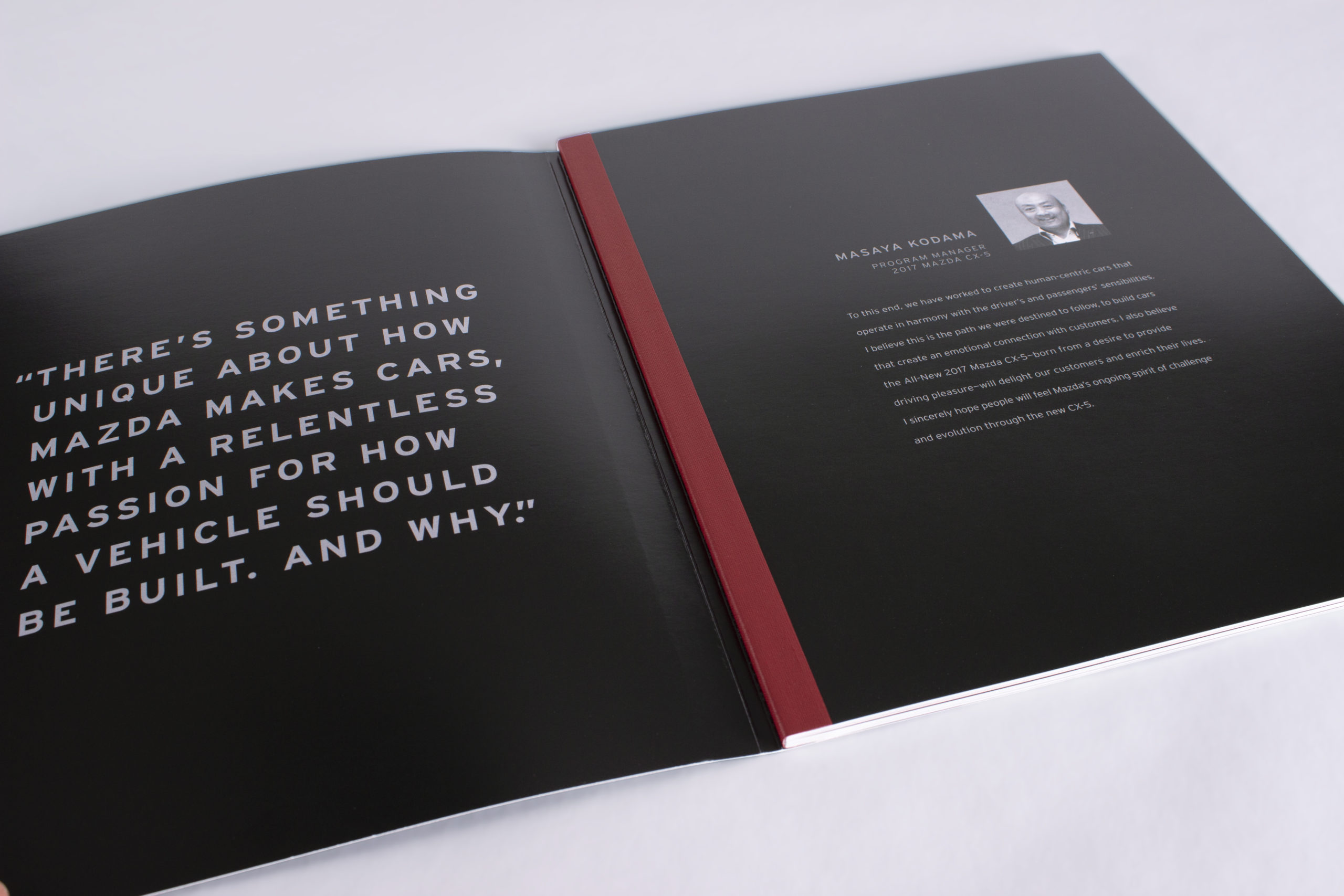

Lay-flat books have seamless spreads with no gutter loss across double-page spreads due to their unique design that allows the book to stay open flat on any surface. This makes them ideal for displaying large-scale images hindered by a spine. Lay-flat photobooks allow you to create panoramic images spread over two pages, without distortion or interruption from the book’s spine. Additionally, they offer more page count options than perfect bindings and can go up to as many as 200 pages if desired.

Printing Quality

Print quality is important when selecting between lay-flat or perfect binding for a book. Lay-flat binding ensures that photos and images are printed on both sides of each page which helps maintain the original quality of the photos and images, in terms of sharpness and color accuracy. This makes it ideal for high-quality, professional photobooks, cookbooks and personal photo albums.

Production Time

When deciding between lay-flat vs perfect binding for a book, production time is an important factor. Lay-flat books take longer to produce than perfect binding because more steps are involved in the binding process.

Perfect binding is much simpler as it involves gluing the spine edge of all the pages together in one step and then trimming them to size. Lay-flat books are preferred when high-quality printing and presentation need to be achieved quickly, as they offer uninterrupted double-page spreads without obstructing the spine or edges of the page. Perfect bindings often have visible spine creasing, which can distort images if not done properly.